Material

Analytical laboratory services

Our laboratory has a highly equipped technical and chemical background, suitable for industrial and research purposes. Our state-of-the-art analytical facilities (ICP-OES, FTIR, SEM-EDX, XRD) and classical chemistry laboratory allow detailed structural and compositional analysis of metallic, non-metallic, composite and coated materials. And our vacuum and protective gas atmosphere annealing furnaces allow targeted modification of material properties. We provide full support for R&D, quality assurance, debugging and process validation.

Materials testing R&D activities

In the field of state-of-the-art materials testing, we are not only available to our industrial partners, but also participate in national and international flagship research projects, contributing to scientific results and social and environmental benefits at European level.

Hydrogen compatibility tests

Hydrogen compatibility and hydrogen damage studies are among our latest research areas. Hydrogen as one of the promising energy carriers of the future and related studies offer new opportunities for our partners, be it in the gas, automotive or commercial sectors.

Advanced materials testing and fracture mechanics analysis

We also provide our partners with the latest technology and state-of-the-art infrastructure in the field of materials testing. Our laboratory is equipped to perform a wide range of destructive (test specimens and small parts), non-destructive, metallographic and structural testing. Our Materials Testing Laboratory is accredited for over 50 types of standard tests.

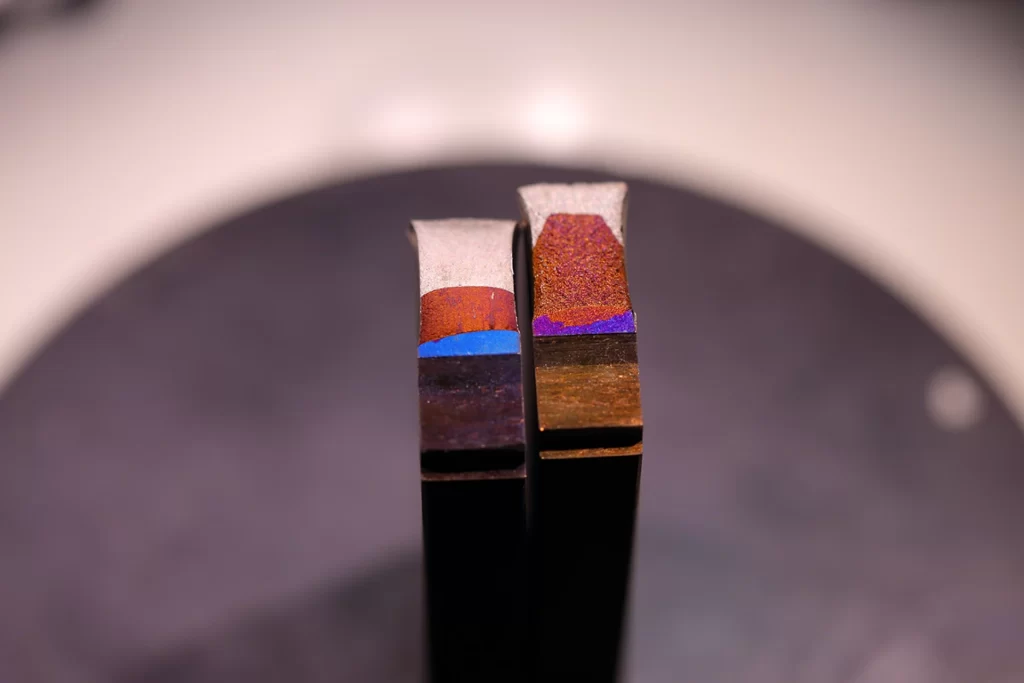

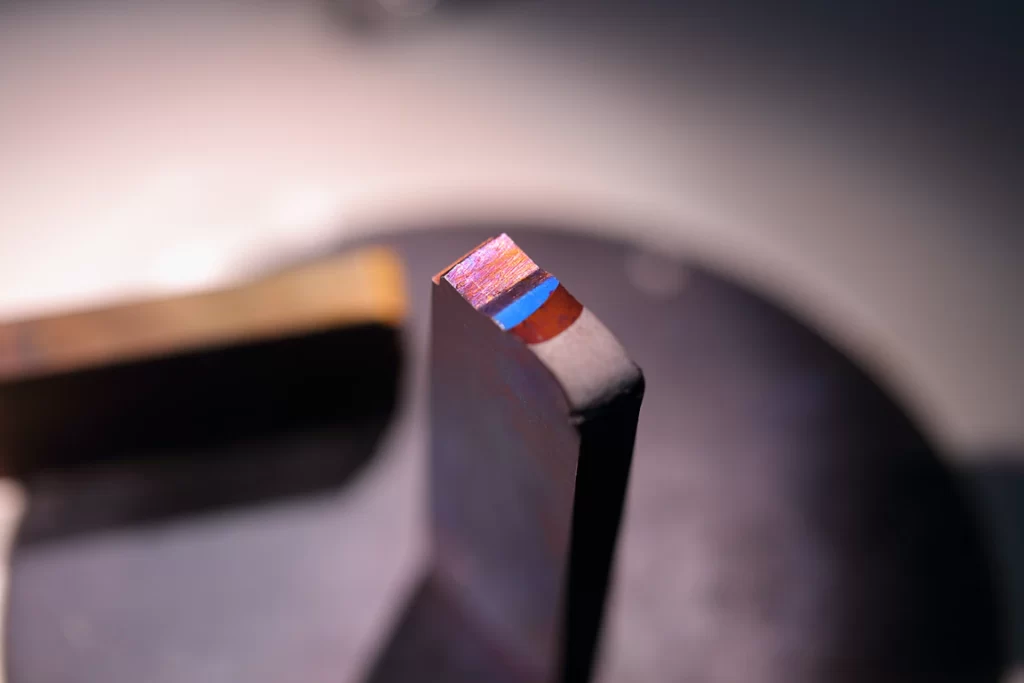

Metallographic tests

Our material testing services include various structural analyses, including metallographic analyses (micro, macro), using state-of-the-art technology to ensure detailed and accurate study of the microstructure of materials, thus enabling the precise identification of grain structures, crystal structures and possible defects.

Use and development of polymers and biopolymers

One of the biggest challenges in today's world is the excessive, often inappropriate, use of plastics and the lack of recycling. Our polymer technology group helps partners to use and develop polymers in a way that meets today's challenges.

Product and technology development, optimisation

The ever-changing needs of industry and end-users require the development of new products and technologies, or the transformation and modernisation of existing ones. With a very broad range of competencies, our development team helps our customers to achieve a wide variety of goals.

Tribological research and development

One of the main profiles of the Engineering Division of the Bay Zoltán Research Institute is the study of tribological processes, including wear, surface fatigue, lubrication properties, friction, and the lifetime of contact surfaces on contact surfaces of machine components and drive train components. The staff of the Division has in-depth knowledge, which, combined with numerical simulation capabilities, allows complex research and development of a complete tribo-system.

Development of new material structures, material structures, alloys, high specific surface area materials

Industrial development is placing ever greater demands on materials. These demands can no longer be met by conventional materials, and there is a growing demand for materials with special properties, usually combined or specially manufactured or treated. By assessing and understanding the needs of our customers, we propose special solutions, which we develop on a laboratory scale and then technologise up to prototype level.